CNC Laser Cutting

Home || Services || CNC Laser Cutting

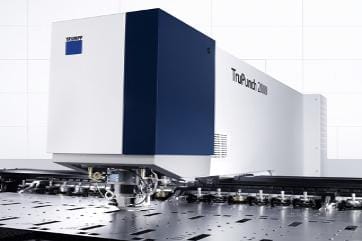

CNC Laser Cutting: Precision Engineering at Its Finest

Transform your manufacturing processes with our state-of-the-art CNC laser cutting services. We deliver exceptional accuracy, efficiency, and quality for your most demanding projects.

Advanced Capabilities

- Superior Precision: Our high-powered laser technology achieves exceptionally fine tolerances and intricate details, making even the most complex designs achievable. Perfect for projects requiring absolute accuracy and consistency.

- Material Versatility: We expertly process a wide range of materials with precision:

- Metals: Steel, Stainless steel, Aluminum

- Specialty materials: Copper, brass

- Custom thicknesses to match your specifications

- Cost-Effective Production: Experience significant cost savings through:

- Minimal material waste with optimized nesting

- No tooling costs or setup charges

- Reduced need for secondary finishing operations

- Reduced need for secondary finishing operations

- Faster production cycles compared to traditional methods

Industry Benefits

- Rapid Prototyping & Production: Whether you need a single prototype or full production run, our automated CNC laser cutting delivers consistent quality and quick turnaround times.

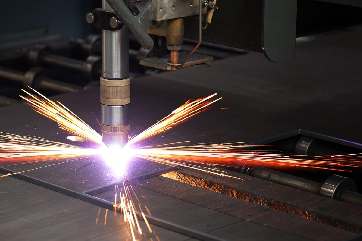

- Superior Finish Quality: Our precision laser technology provides:

- Clean, burr-free edges

- Exceptional surface finish

- Minimal heat-affected zones

- Reduced need for post-processing

- Design Freedom: Bring your most challenging designs to life:

- Complex geometries and intricate patterns

- Tight tolerances and fine details

- Consistent repeatability for high-volume production

- Quick design modifications without tooling changes

Applications

- Versatile Solutions: Our laser cutting capabilities serve diverse industries:

- Automotive and aerospace components

- Industrial machinery parts

- Electronic enclosures

- Architectural elements

- Custom fabrication projects

CNC Punching

CNC Punching CNC Bending

CNC Bending Fabrication

Fabrication Powder Coating

Powder Coating PU Foam Gasketing

PU Foam Gasketing Liquid Painting

Liquid Painting Bus Bar Manufacturer

Bus Bar Manufacturer