Powder Coating

Home || Services || Powder Coating

Powder Coating: Superior Surface Protection

Transform your components with our advanced powder coating services. We deliver durable, environmentally conscious finishes that combine aesthetic appeal with superior protection.

Advanced Capabilities

- Premium Finish Quality: Our state-of-the-art powder coating system delivers exceptional results:

- Uniform coverage and adhesion

- Consistent color matching

- Multiple texture options

- Custom finish solutions

- Superior edge coverage

- Environmentally Responsible Process: We prioritize sustainability through:

- Solvent-free coating technology

- LPG-powered curing ovens for cleaner operations

- Minimal waste production

- Reduced environmental impact

- Energy-efficient processes

Performance Benefits

- Long-Term Protection: Our powder coating provides outstanding durability:

- Enhanced scratch resistance

- Superior corrosion protection

- UV and weather resistance

- Chemical resistance

- Impact resistance

- Cost-Effective Solution: Experience lasting value through:

- Extended product life

- Reduced maintenance needs

- Higher durability than liquid paint

- Efficient batch processing

- Quick turnaround times

Applications

- Versatile Finishing Options: Our powder coating serves diverse needs:

- Industrial equipment

- Outdoor furniture

- Architectural components

- Consumer products

- Custom applications

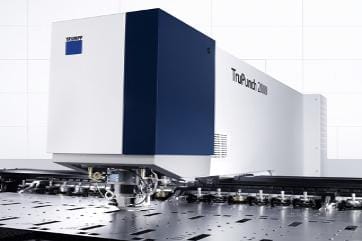

CNC Punching

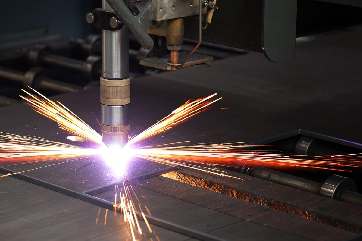

CNC Punching CNC Laser Cutting

CNC Laser Cutting CNC Bending

CNC Bending Fabrication

Fabrication Powder Coating

Powder Coating PU Foam Gasketing

PU Foam Gasketing Liquid Painting

Liquid Painting Bus Bar Manufacturer

Bus Bar Manufacturer